In a strategic move to catapult its manufacturing prowess into the future, Hyundai is poised to make a dramatic leap with the incorporation of thousands of robots from Boston Dynamics. Coupled with cutting-edge advances in humanoid robotics, this development promises transformative impacts on production capabilities and operational efficiencies.

The Strategic Acquisition of Boston Dynamics Robots

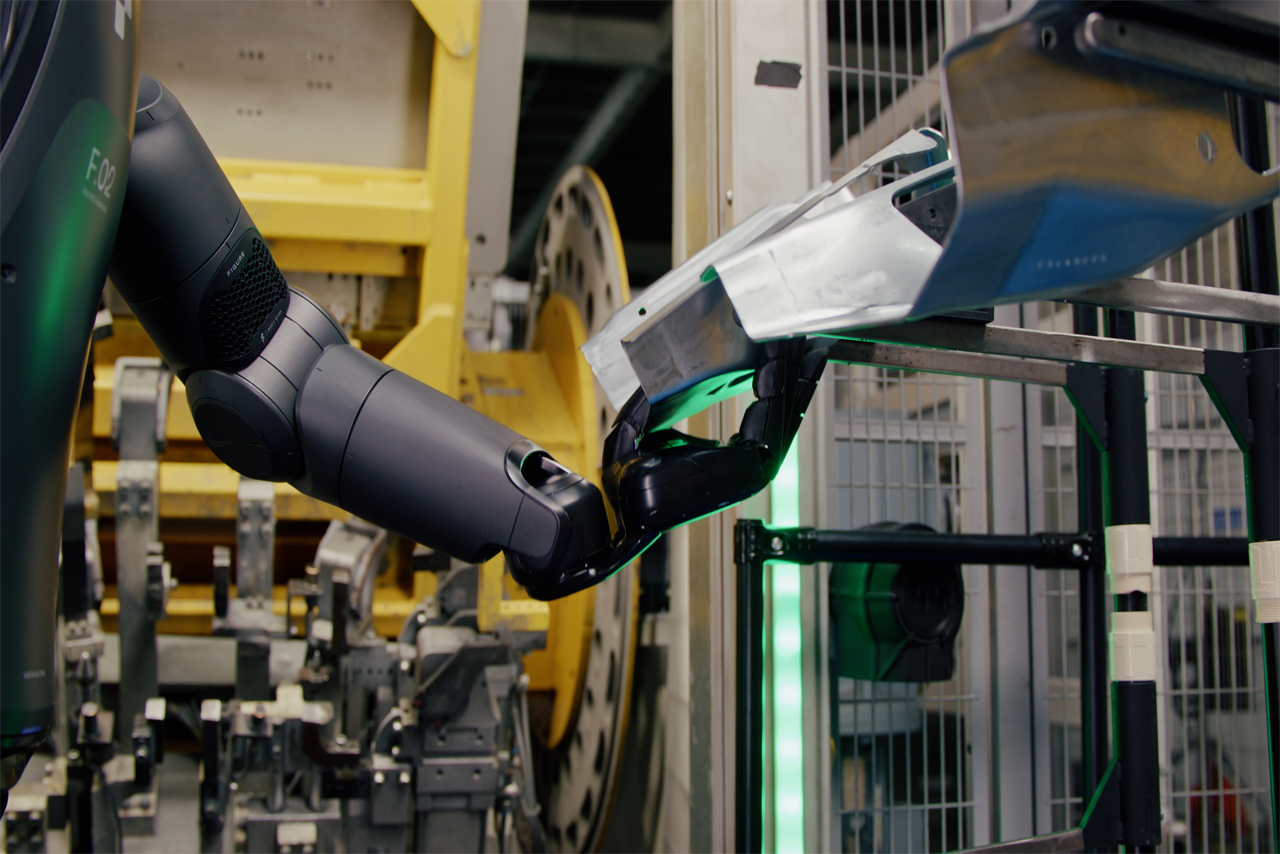

Hyundai has made headlines with its decision to acquire a significant number of Boston Dynamics robots for its manufacturing facilities. This decision highlights a pivotal shift towards automation and intelligent robotics in manufacturing industries worldwide.

Key Benefits of Boston Dynamics’ Robots

- Increased Efficiency: The integration of these robots is expected to significantly boost manufacturing efficiency by minimizing human error and allowing continuous operation.

- Flexibility: Boston Dynamics’ robots bring exceptional adaptability, capable of handling a variety of tasks across different production lines.

- Precision and Speed: These robots are renowned for their precise operations, which are performed at speeds unmatchable by human hands.

With these notable benefits, Hyundai’s investment in Boston Dynamics robots is expected to set a new standard for automated production facilities worldwide.

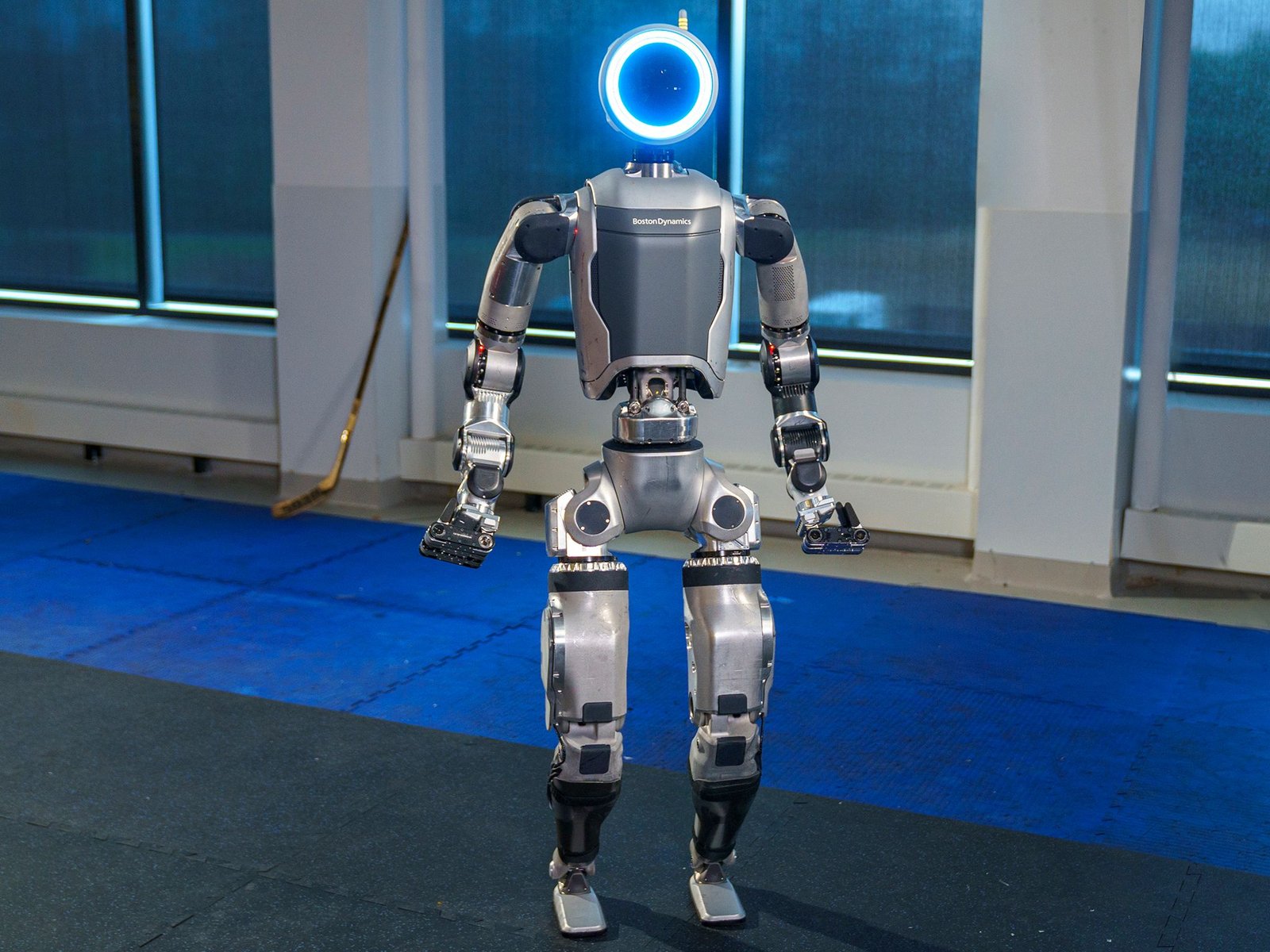

Advancements in Humanoid Robotics

In addition to acquiring Boston Dynamics robots, Hyundai is also venturing into humanoid robotics, paving the way for futuristic advancements in manufacturing environments.

The Evolution of Humanoid Robotics

Humanoid robots have long captivated imaginations, but only recently have they started to exhibit capabilities that closely emulate human behaviors. Recent advancements include:

- Improved Mobility: New humanoid designs demonstrate enhanced walking and balancing abilities, enabling them to navigate complex terrains similar to humans.

- Advanced AI: Incorporation of sophisticated AI systems that allow robots to analyze and respond to dynamic environments effectively.

- Enhanced Dexterity: Efforts to mimic human hand movements have resulted in robots capable of performing delicate tasks that require precision.

Impact on Manufacturing by Humanoids

These advances in humanoid robotics hold promise for profound shifts in how manufacturing companies operate. They can autonomously work alongside human employees, manage hazardous materials, and ascertain repairs, optimizing the workflow.

This strategic blend of traditional robotics and humanoid technologies is set to revolutionize manufacturing, contributing to more resilient and adaptive production systems.

The Broader Implications of Hyundai’s Investment

Hyundai’s inclusion of high-tech robotics extends beyond manufacturing. It highlights the growing necessity for industries to adapt and evolve in the face of the Fourth Industrial Revolution.

Industry Transformation

Hyundai’s move serves as an industry beacon, urging other automakers and manufacturers to consider integrating robotic technologies for substantial competitive advantages. Here are some implications:

- Global Leadership: By pioneering the application of advanced robotics, Hyundai is positioning itself as a leader in both automotive production and technology integration.

- Job Creation and Diversification: While robots take over repetitive tasks, there will be a growth in high-skill job sectors requiring expertise in robot maintenance and AI.

- Sustainability: Robotics can lead to more efficient energy usage and reduced waste, contributing to a more sustainable production model.

Conclusion

Hyundai’s investment in Boston Dynamics’ robots and humanoid robotics reflects a paradigm shift in manufacturing. By harnessing the strengths of automation and human-mimicking robots, Hyundai is paving the way for a future where technology not only supports but enhances human industry. As these technologies continue to evolve, they promise to redefine what is possible in manufacturing and beyond.

With the global manufacturing landscape ripe for transformation, Hyundai’s strides in robotics integration serve as both inspiration and a challenge for industries worldwide to embrace the future.